Communication and Control

We are a fast-growing system integrator delivering advanced Communication and Control Electronics alongside Precision Weighing and Balancing Systems for railways. By combining engineering depth with proven technologies, we enable safer, smarter, and more efficient rail operations.

Core Rail Technology Solutions

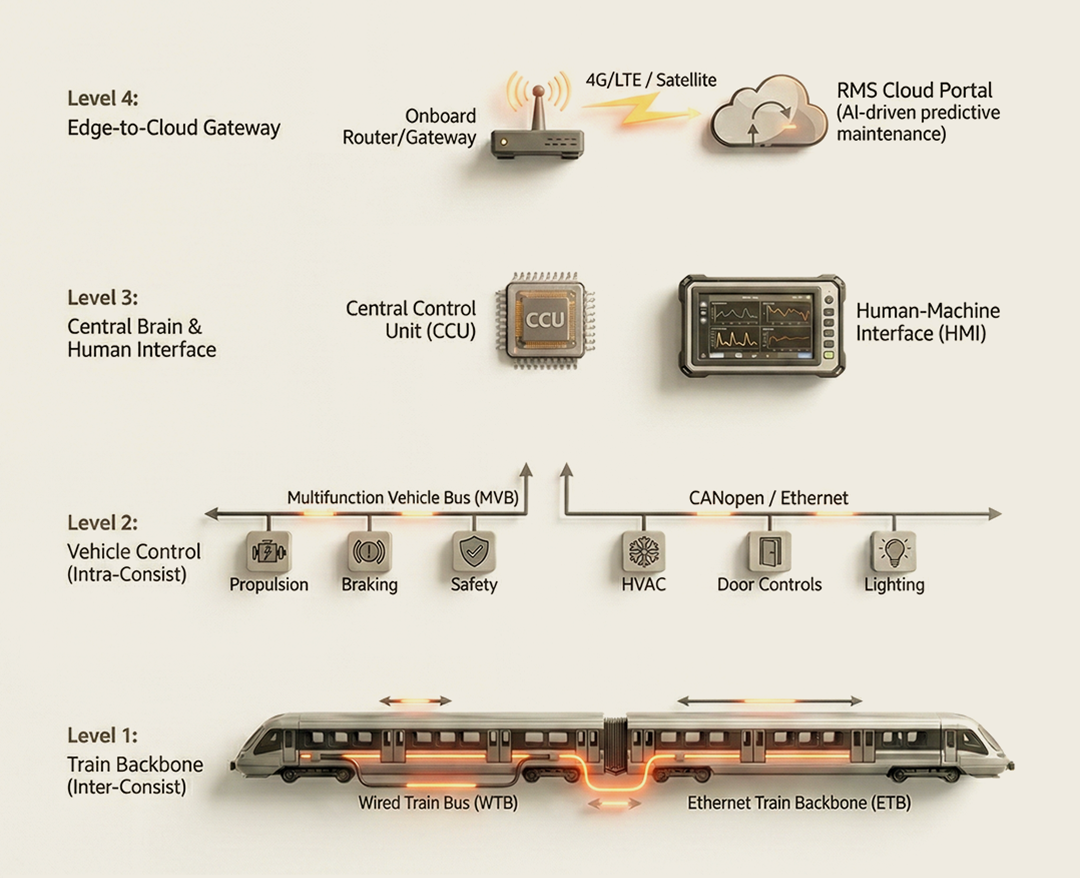

Train Control & Management System (TCMS)

The Intelligent Backbone of Rolling Stock Architecture

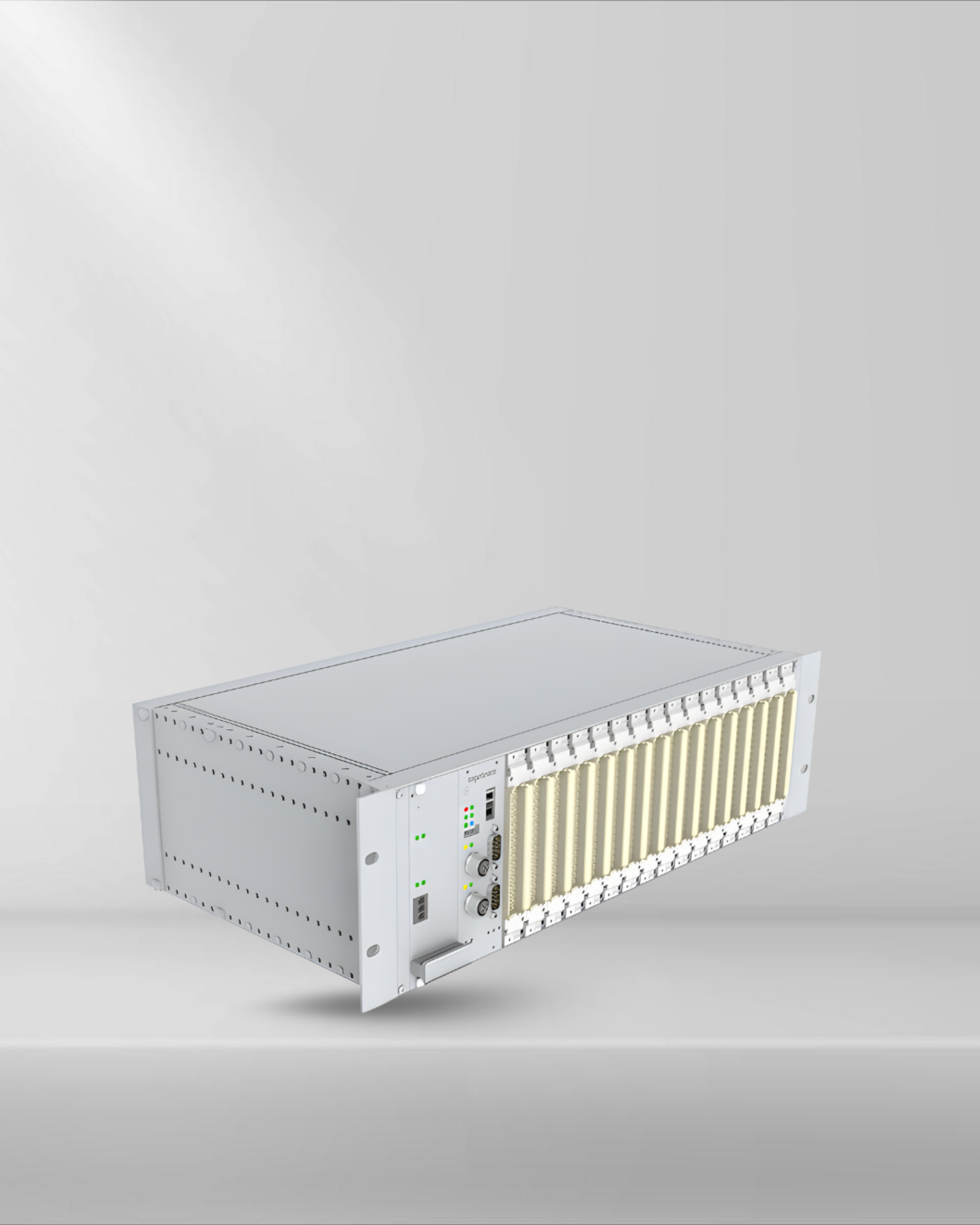

Klovertel’s TCMS is a high-availability, modular platform engineered to serve as the single point of control for all onboard subsystems. It is designed to meet the rigorous demands of modern high-speed trains, metros, and locomotives, ensuring seamless interoperability through international standardization.

Network Standards & Protocols: Our architecture fully complies with the IEC 61375 (Train Communication Network - TCN) series. It supports a hybrid of legacy and next-generation fieldbuses, including Multifunction Vehicle Bus (MVB) for time-critical intra-consist data, Wire Train Bus (WTB) for automatic inauguration between coupled units, and Ethernet Train Backbone (ETB) using the Train Real-Time Data Protocol (TRDP) for high-bandwidth IP connectivity.

Safety & Reliability: The system is built on EN 50155 compliant hardware, designed to operate reliably under extreme temperature, shock, and vibration conditions. We support Safety Integrity Level 2 (SIL 2) development, utilizing Safe Data Transmission (SDTv2) protocols for mission-critical functions like door control and braking release.

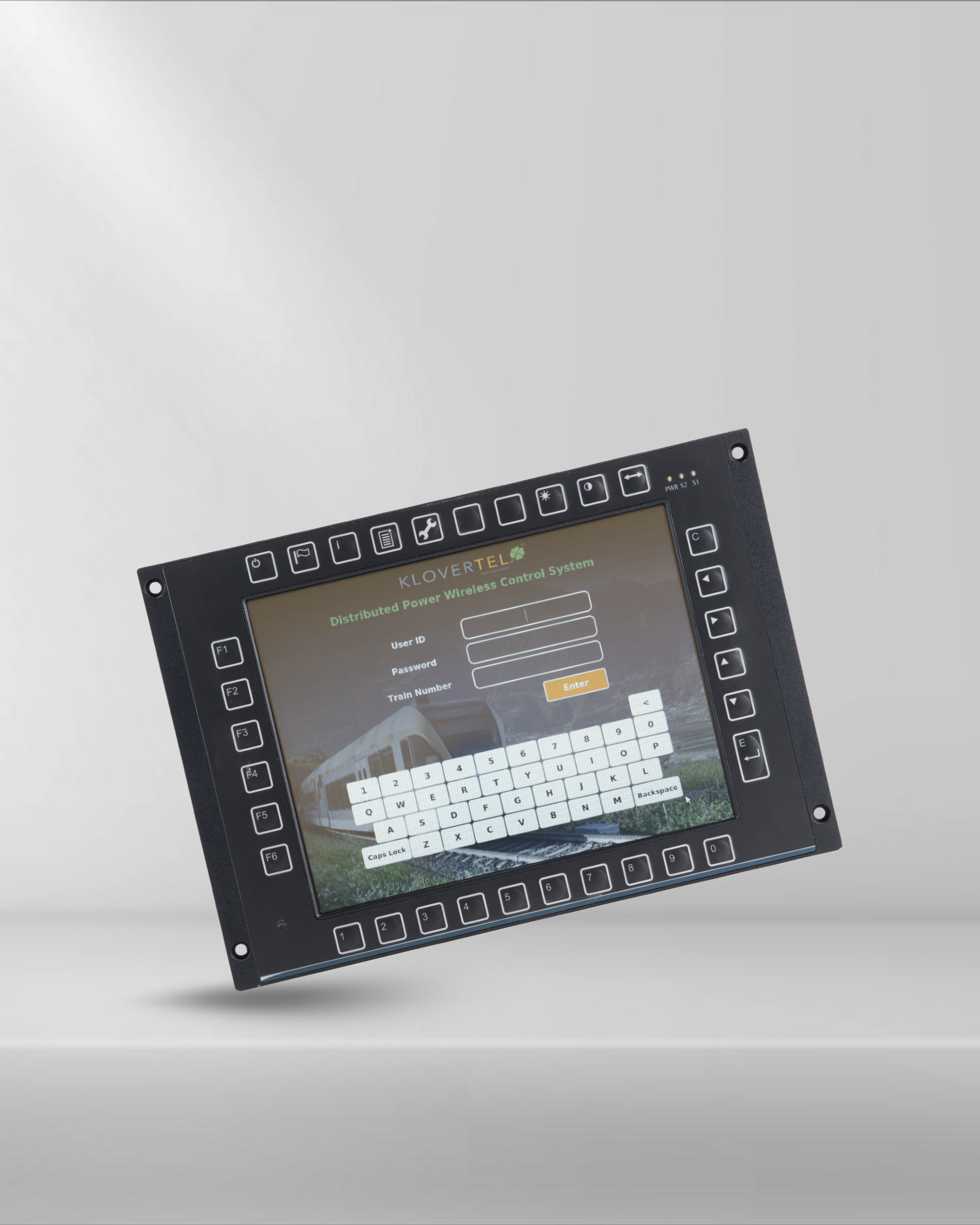

Advanced Diagnostics: Featuring a high-resolution Human-Machine Interface (HMI), the TCMS provides real-time visualization of over 250 fault types. It acts as a gateway for the centralized drive control and decentralized management of HVAC, PIS, and propulsion systems.

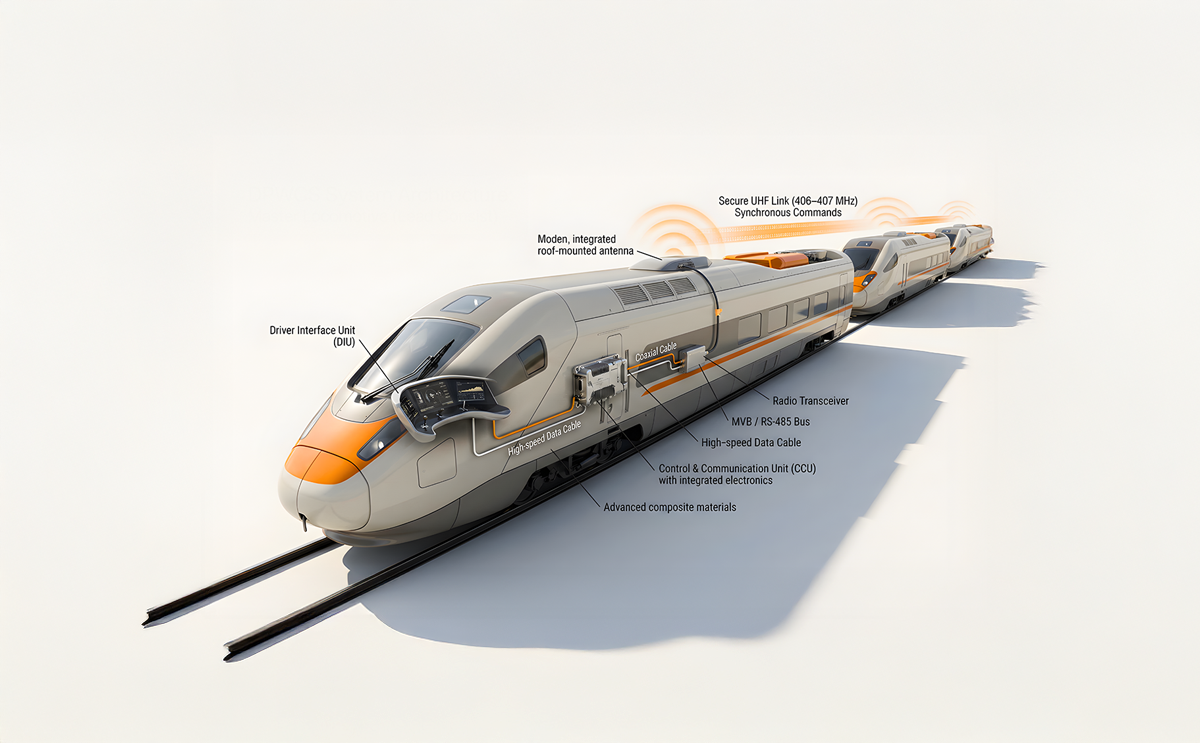

Distributed Power Wireless Control System (DPWCS)

Wireless Synchronous Command for Heavy-Haul Operations.

The DPWCS is an advanced radio-frequency-based control solution that enables multiple locomotives to operate as a single, synchronized unit across a train consist. It is specifically designed to maximize tractive effort and fuel efficiency in long-haul heavy rail operations.

Communication Layer: The system operates in the licensed UHF (406–407 MHz) or VHF bands, utilizing 4-state FSK modulation to achieve a reliable signaling rate. This wireless link facilitates real-time tele-command and telemetry exchange between a Lead (Master) locomotive and up to four Remote (Slave) units distributed throughout the train.

Fail-Safe Synchronization: At the core of the system is the Control & Communication Unit (CCU) and the Brake Interface Unit (BIU). The BIU ensures high-precision control of Automatic (Train), Independent (Loco), and Emergency brakes with an accuracy of 0.05 kg/cm². In the event of a communication loss, the system triggers a fail-safe "Comms-Loss" protocol, returning remote units to a safe idle state.

Intelligent Automation: The system integrates GPS-based Neutral Section Negotiation, allowing trailing locomotives to automatically manage power transitions based on precise coordinates, preventing equipment stress and ensuring smooth passage through restricted power zones.

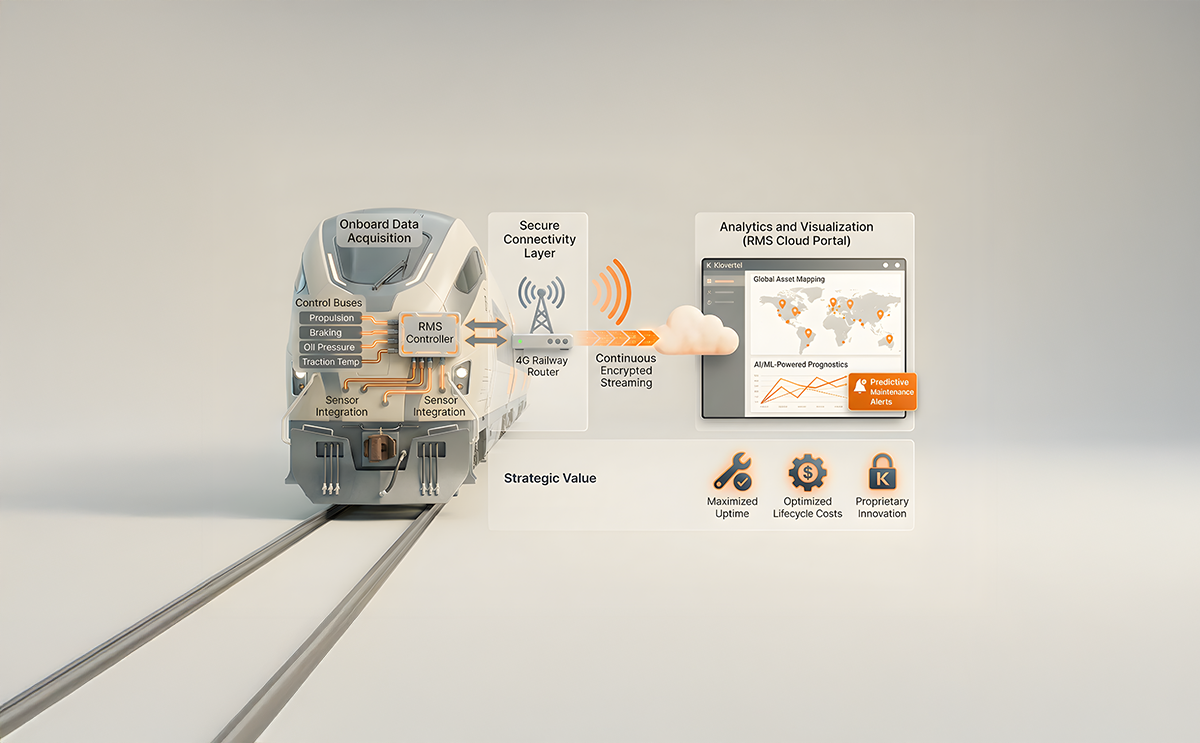

Remote Monitoring System (RMS)

Cloud-Native Diagnostics and Predictive Asset Intelligence

Klovertel’s RMS is a sophisticated IoT-driven platform that provides deep visibility into locomotive health and operational efficiency. It enables a transition from reactive maintenance to a data-driven Condition-Based Maintenance (CBM) strategy.

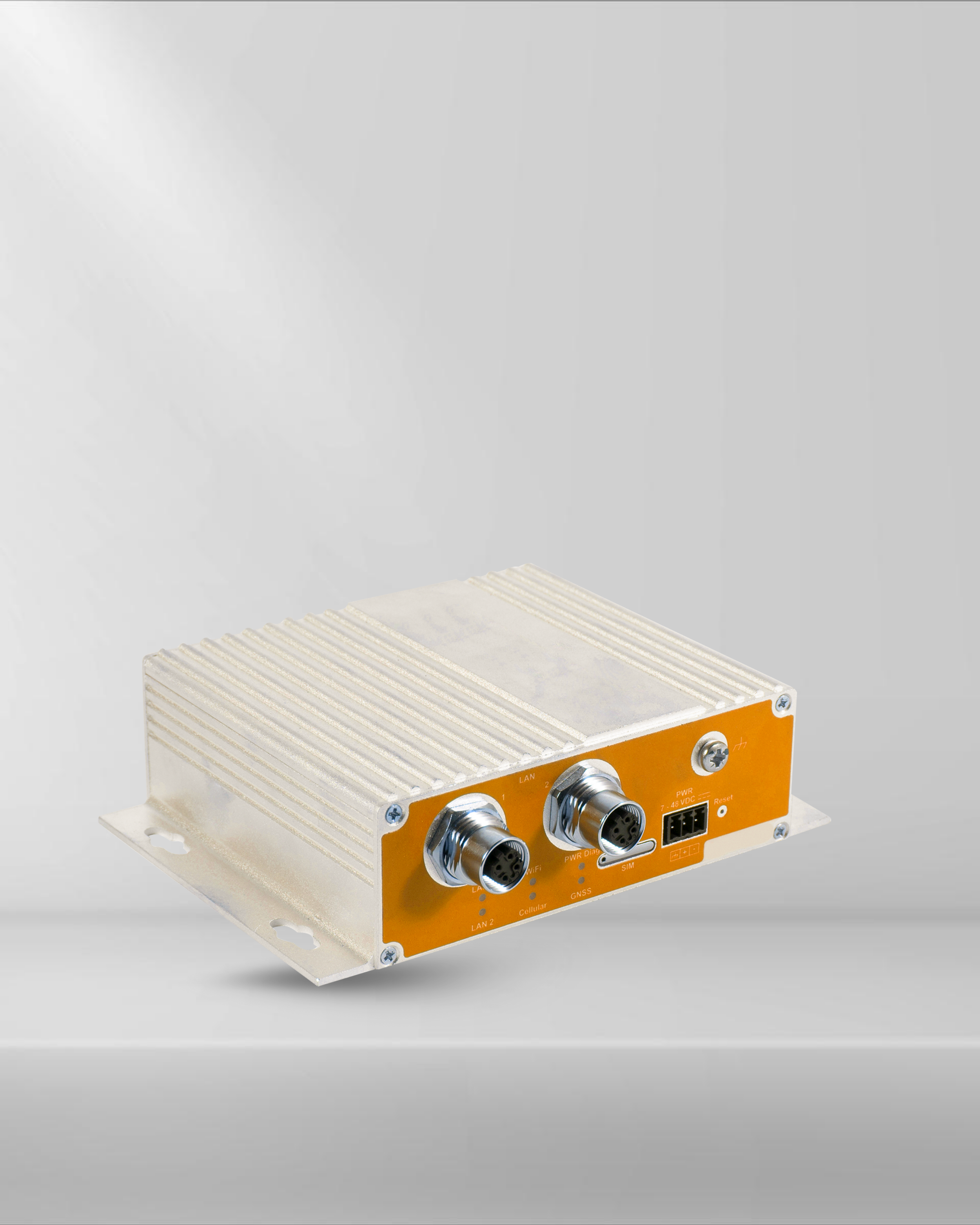

Data Acquisition & Transmission: The onboard hardware continuously polls the locomotive's internal buses via MVB or CAN or ETH to capture critical process variables—including traction temperatures, speed, catenary voltage, and oil pressure. Data is securely transmitted to a centralized cloud server via high-speed 4G/LTE or global satellite networks at a refresh rate as low as seconds.

AI/ML Prognostics: Our back-end analytics engine utilizes proprietary Machine Learning (ML) models to analyze massive datasets, identifying subtle patterns indicative of incipient failures. This proactive failure prediction significantly reduces "Line-of-Road" failures and optimizes spare parts management.

Operational Visibility: The RMS portal offers real-time fleet mapping through GPS- enabled tracking, graphical trend analysis for individual components, and automated SMS/Email alerts for critical fault conditions, ensuring that maintenance teams are informed before the locomotive enters the shed.