Precision Weighing and Balancing

At Klovertel, we recognize that precision weighing is the cornerstone of safe and efficient rail operations worldwide. Unbalanced loads and inaccurate weight measurements are primary contributors to premature track wear, infrastructure damage, and derailment risks. Our Precision Weighing and Balancing solutions, delivered through our exclusive partnership with Trakblaze, provide the most advanced metrological technology available to the global rail industry.

These systems are engineered for high-accuracy performance in diverse environments—from high-speed mainlines to heavy-haul mining corridors and specialized maintenance workshops. By integrating these solutions, rail operators can ensure regulatory compliance, optimize fuel economy through balanced loading, and protect multi-million dollar rolling stock assets.

High-Speed Train Weighbridge (EIMWB) – Infinity HS

Non-Intrusive, High-Velocity Weigh-In-Motion (WIM)

The Infinity HS represents the pinnacle of high-speed weighing technology, enabling the accurate measurement of train loads at operational speeds without disrupting traffic flow. It is designed for high-volume rail networks where stopping or slowing trains is not an option.

Operational Velocity: Capable of weighing trains at speeds up to 80 km/h, making it one of the fastest trade-approved systems globally.

Technical Architecture: The system utilizes a robust, load-cell-based structure consisting of 6 electronic weigh sleepers and 12 dummy sleepers. This configuration creates a solid weighing zone that ensures stability and accuracy across the entire train consist.

Metrological Accuracy: Delivers high-precision results with a total train accuracy of ± 0.25% – 0.5%.

Installation & Standards:

No Rail Alteration: Features a unique "no rail cutting, welding, or grinding" installation process, which preserves the structural integrity of existing tracks and reduces downtime to typically 2–3 days.

Compliance: Government trade-approved (e.g., NMI 6/14H/8) for commercial billing and regulatory enforcement.

Durability: Temperature-compensated for operation from -10°C to +80°C and upgradeable to handle up to 50t per axle.

Connectivity: Seamless data integration via TCP/IP allows for remote monitoring and real-time weight reporting accessible from any global location via the internet.

Mobile Train Weigher & Balancing System – MTW-MS

Portable Precision: "Take the Scale to the Train"

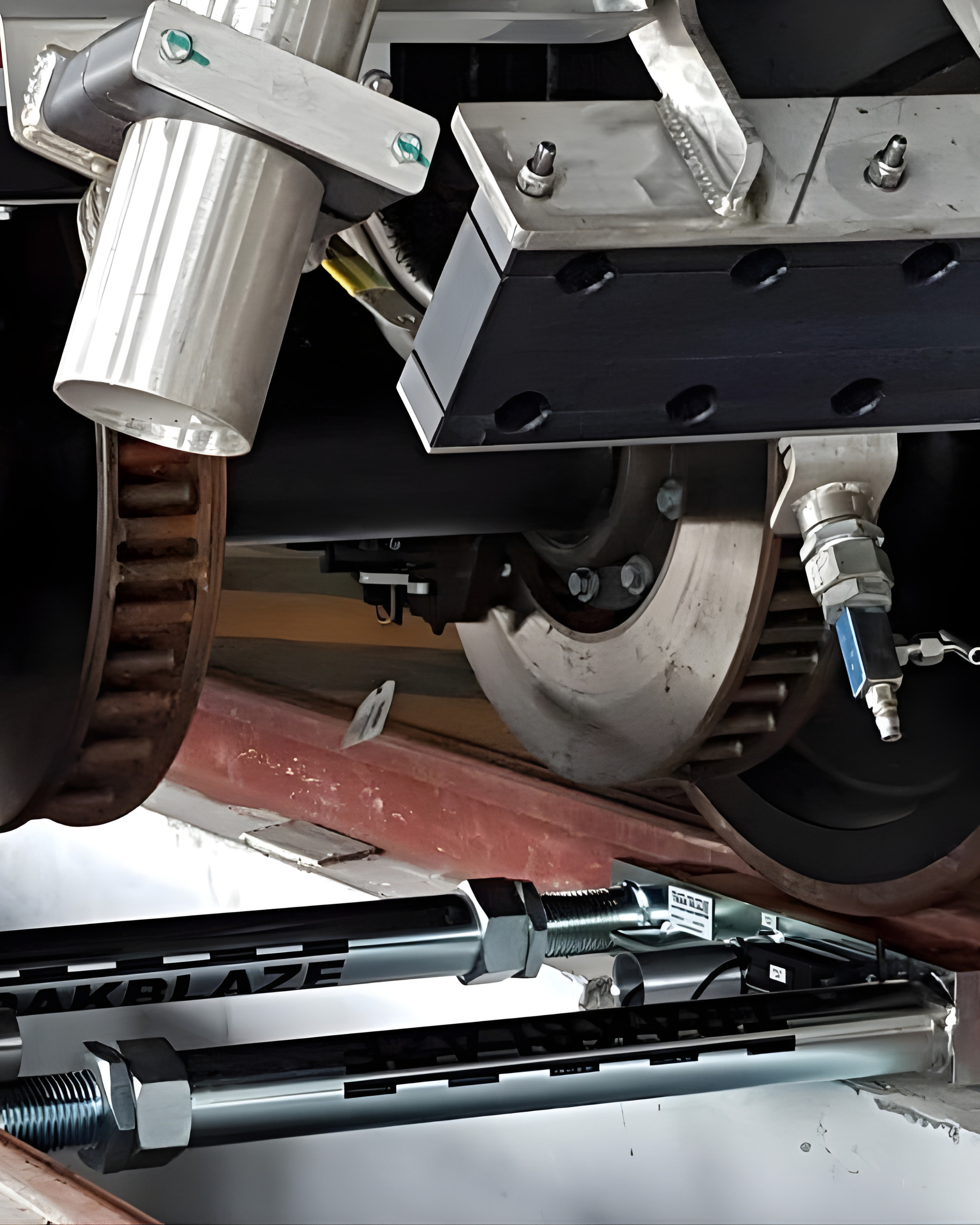

The MTW-MS is a versatile, mobile weighing and balancing solution designed for rapid deployment. It is an essential tool for field spot-checks, rail manufacturing, and maintenance depots requiring precise wheel, axle, and bogie balancing to prevent derailments.

Portability & Deployment: The system is lightweight and compact enough to be transported in the boot of a standard vehicle. A two-man team can complete the installation in approximately 15–30 minutes without any track downtime or costly civil works.

Balancing & Multi-System Capability:

Advanced Balancing: The MTW-MS measures individual wheel, axle, and bogie weights, providing the data necessary to adjust load distribution and simulate operational stresses.

Scalability: Supports the connectivity of up to 8 or 12 base units to weigh multiple bogies or entire railcars simultaneously.

Technical Specifications:

Capacity: Standard capacity of 17.5t per wheel (35t per axle), with heavy-duty options available.

Static & Dynamic Modes: Engineered for both stationary weighing (accuracy ±0.5%) and in-motion "spot check" weighing.

Environmental Protection: Built with high-quality tool and mild steel, featuring IP-67 or IP-68 protection ratings to withstand harsh outdoor and workshop conditions.

Wireless Connectivity: Modern configurations utilize wireless receivers and rugged tablets, eliminating the need for cables and allowing for greater operational flexibility in complex workshop environments.