Global Rail Innovation: Connectivity, Control, and Precision

Klovertel is a premier provider of advanced, end-to-end technology solutions for the global rail industry. With over a decade of exclusive focus on the rail sector, we specialize in delivering world-class technologies that drive connectivity and control for modern infrastructure. Our business is built on a foundation of 22+ years of industry experience, serving a prestigious portfolio of international clients and government entities.

At Klovertel, we bridge the gap between global innovation and localized excellence. As the sole and exclusive partner in India for industry giants—including Ingeteam (Spain), Trakblaze (Australia), and Pfiffner (Switzerland)—we integrate the world’s most precise weighing and power technologies into comprehensive, mission-critical systems.

Railways –

Communication and Control

We are a fast-growing system integrator delivering advanced Communication and Control Electronics alongside Precision Weighing and Balancing Systems for railways. By combining engineering depth with proven technologies, we enable safer, smarter, and more efficient rail operations.

Core Rail Technology Solutions

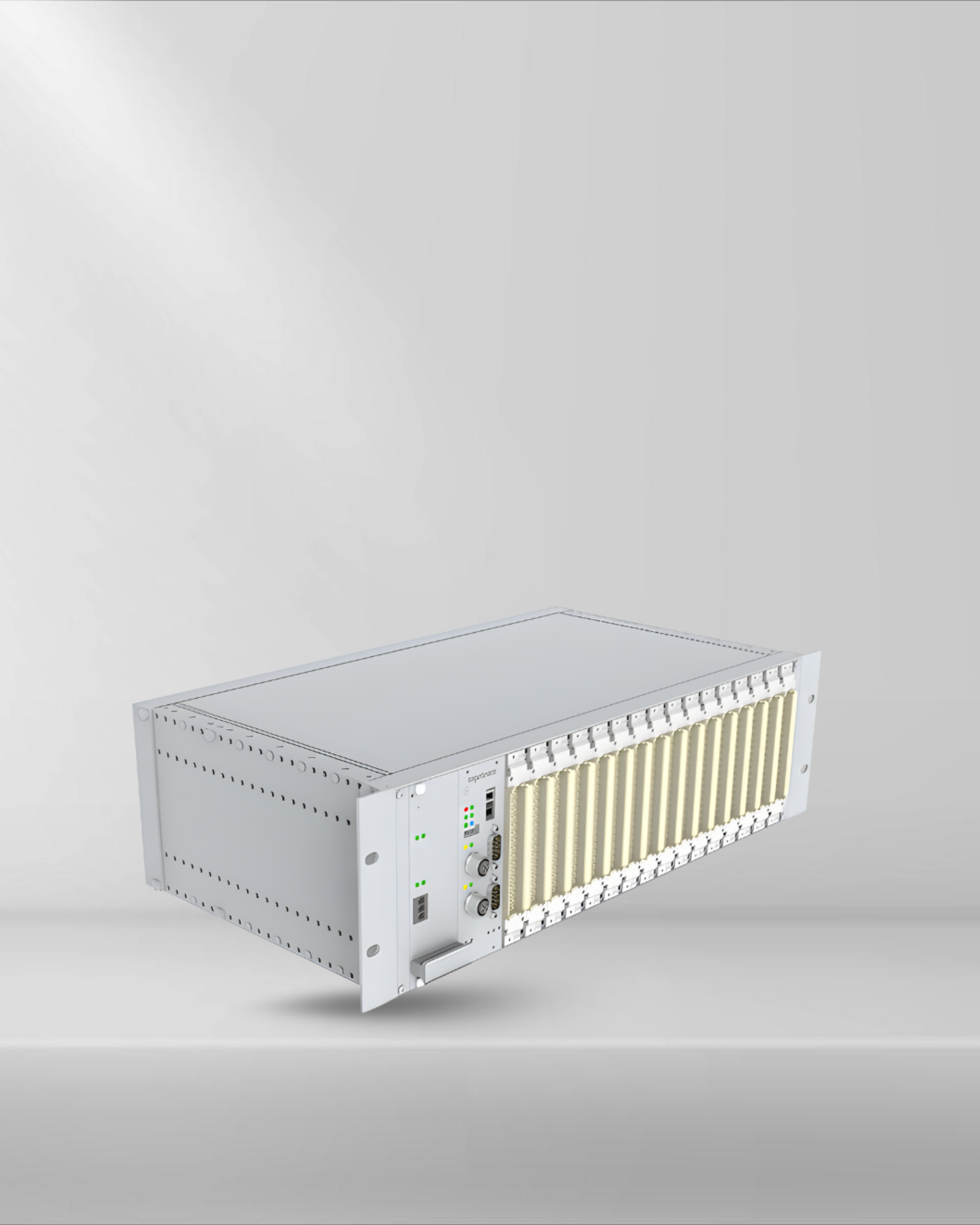

Train Control & Management System (TCMS)

The Intelligent Backbone of Rolling Stock Architecture

Klovertel’s TCMS is a high-availability, modular platform engineered to serve as the single point of control for all onboard subsystems. It is designed to meet the rigorous demands of modern high-speed trains, metros, and locomotives, ensuring seamless interoperability through international standardization.

Network Standards & Protocols: Our architecture fully complies with the IEC 61375 (Train Communication Network - TCN) series. It supports a hybrid of legacy and next-generation fieldbuses, including Multifunction Vehicle Bus (MVB) for time-critical intra-consist data, Wire Train Bus (WTB) for automatic inauguration between coupled units, and Ethernet Train Backbone (ETB) using the Train Real-Time Data Protocol (TRDP) for high-bandwidth IP connectivity.

Safety & Reliability: The system is built on EN 50155 compliant hardware, designed to operate reliably under extreme temperature, shock, and vibration conditions. We support Safety Integrity Level 2 (SIL 2) development, utilizing Safe Data Transmission (SDTv2) protocols for mission-critical functions like door control and braking release.

Advanced Diagnostics: Featuring a high-resolution Human-Machine Interface (HMI), the TCMS provides real-time visualization of over 250 fault types. It acts as a gateway for the centralized drive control and decentralized management of HVAC, PIS, and propulsion systems.

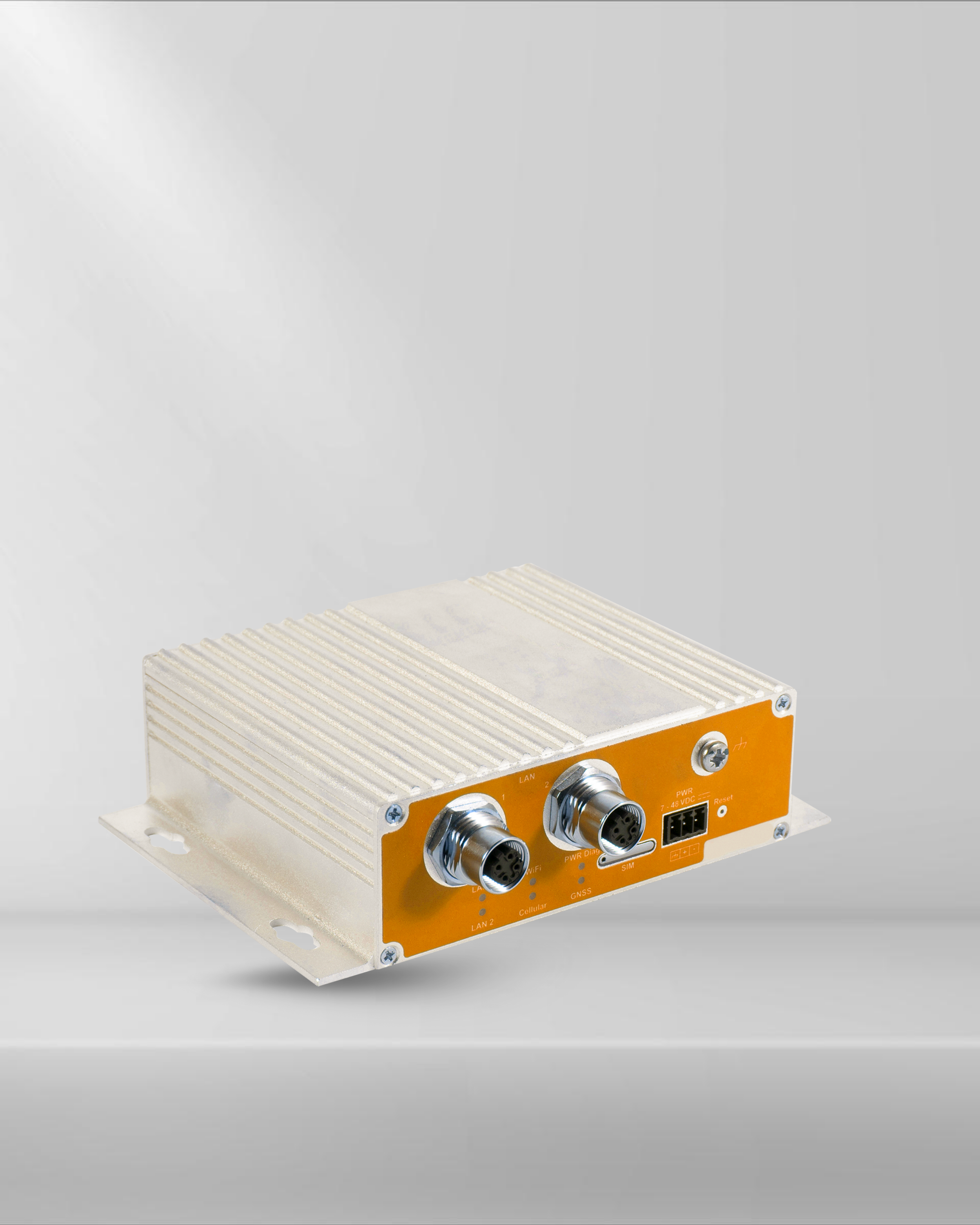

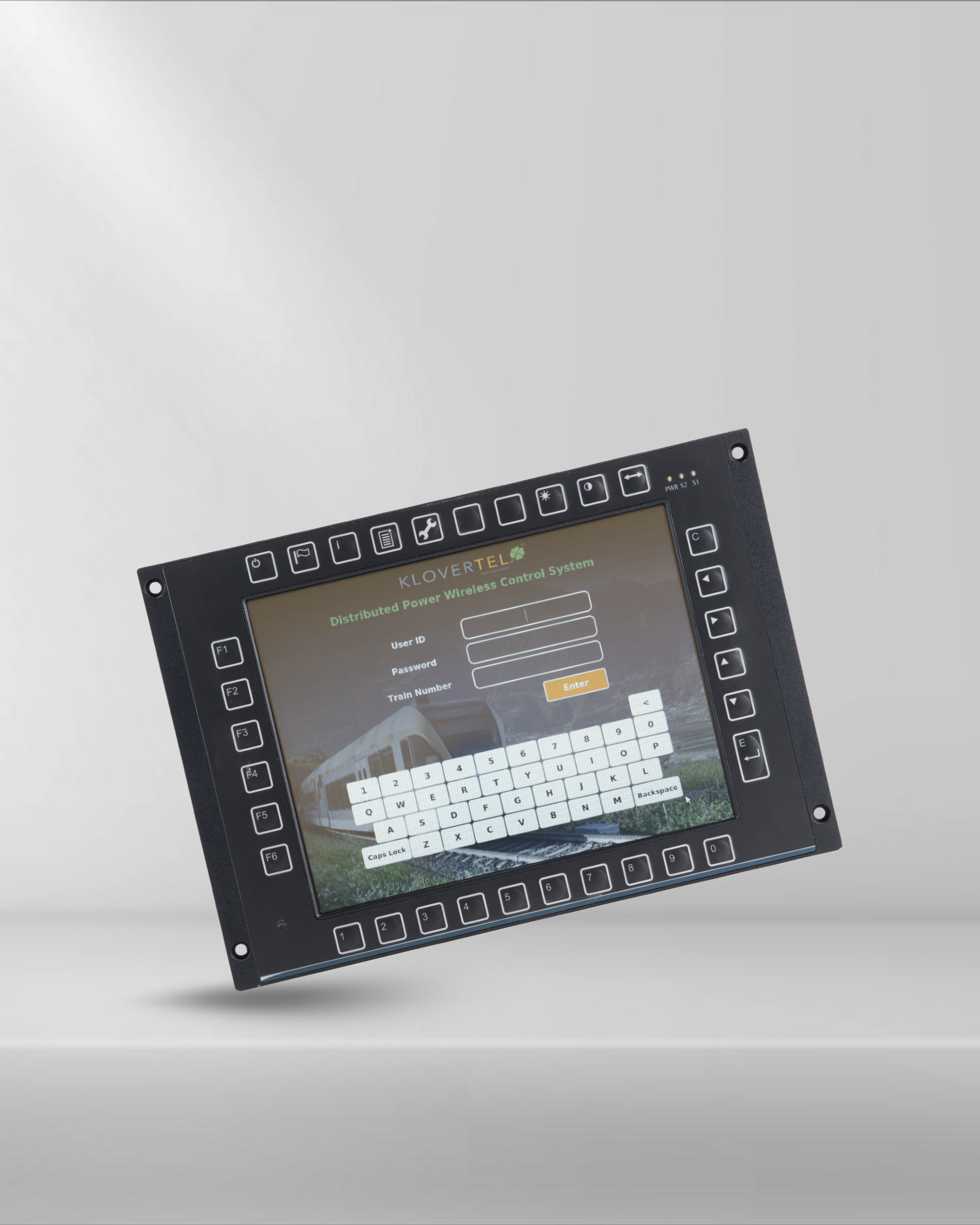

Distributed Power Wireless Control System (DPWCS)

Wireless Synchronous Command for Heavy-Haul Operations.

The DPWCS is an advanced radio-frequency-based control solution that enables multiple locomotives to operate as a single, synchronized unit across a train consist. It is specifically designed to maximize tractive effort and fuel efficiency in long-haul heavy rail operations.

Communication Layer: The system operates in the licensed UHF (406–407 MHz) or VHF bands, utilizing 4-state FSK modulation to achieve a reliable signaling rate. This wireless link facilitates real-time tele-command and telemetry exchange between a Lead (Master) locomotive and up to four Remote (Slave) units distributed throughout the train.

Fail-Safe Synchronization: At the core of the system is the Control & Communication Unit (CCU) and the Brake Interface Unit (BIU). The BIU ensures high-precision control of Automatic (Train), Independent (Loco), and Emergency brakes with an accuracy of 0.05 kg/cm². In the event of a communication loss, the system triggers a fail-safe "Comms-Loss" protocol, returning remote units to a safe idle state.

Intelligent Automation: The system integrates GPS-based Neutral Section Negotiation, allowing trailing locomotives to automatically manage power transitions based on precise coordinates, preventing equipment stress and ensuring smooth passage through restricted power zones.

Remote Monitoring System (RMS)

Wireless Synchronous Command for Heavy-Haul Operations.

The DPWCS is an advanced radio-frequency-based control solution that enables multiple locomotives to operate as a single, synchronized unit across a train consist. It is specifically designed to maximize tractive effort and fuel efficiency in long-haul heavy rail operations.

Communication Layer: The system operates in the licensed UHF (406–407 MHz) or VHF bands, utilizing 4-state FSK modulation to achieve a reliable signaling rate. This wireless link facilitates real-time tele-command and telemetry exchange between a Lead (Master) locomotive and up to four Remote (Slave) units distributed throughout the train.

Fail-Safe Synchronization: At the core of the system is the Control & Communication Unit (CCU) and the Brake Interface Unit (BIU). The BIU ensures high-precision control of Automatic (Train), Independent (Loco), and Emergency brakes with an accuracy of 0.05 kg/cm². In the event of a communication loss, the system triggers a fail-safe "Comms-Loss" protocol, returning remote units to a safe idle state.

Intelligent Automation: The system integrates GPS-based Neutral Section Negotiation, allowing trailing locomotives to automatically manage power transitions based on precise coordinates, preventing equipment stress and ensuring smooth passage through restricted power zones.

Railways –

Precision Weighing and Balancing

At Klovertel, we recognize that precision weighing is the cornerstone of safe and efficient rail operations worldwide. Unbalanced loads and inaccurate weight measurements are primary contributors to premature track wear, infrastructure damage, and derailment risks. Our Precision Weighing and Balancing solutions, delivered through our exclusive partnership with Trakblaze, provide the most advanced metrological technology available to the global rail industry.

These systems are engineered for high-accuracy performance in diverse environments—from high-speed mainlines to heavy-haul mining corridors and specialized maintenance workshops. By integrating these solutions, rail operators can ensure regulatory compliance, optimize fuel economy through balanced loading, and protect multi-million dollar rolling stock assets.

High-Speed Train Weighbridge (EIMWB) – Infinity HS

Non-Intrusive, High-Velocity Weigh-In-Motion (WIM)

The Infinity HS represents the pinnacle of high-speed weighing technology, enabling the accurate measurement of train loads at operational speeds without disrupting traffic flow. It is designed for high-volume rail networks where stopping or slowing trains is not an option.

Operational Velocity: Capable of weighing trains at speeds up to 80 km/h, making it one of the fastest trade-approved systems globally.

Technical Architecture: The system utilizes a robust, load-cell-based structure consisting of 6 electronic weigh sleepers and 12 dummy sleepers. This configuration creates a solid weighing zone that ensures stability and accuracy across the entire train consist.

Metrological Accuracy: Delivers high-precision results with a total train accuracy of ± 0.25% – 0.5%.

Installation & Standards:

No Rail Alteration: Features a unique "no rail cutting, welding, or grinding" installation process, which preserves the structural integrity of existing tracks and reduces downtime to typically 2–3 days.

Compliance: Government trade-approved (e.g., NMI 6/14H/8) for commercial billing and regulatory enforcement.

Durability: Temperature-compensated for operation from -10°C to +80°C and upgradeable to handle up to 50t per axle.

Connectivity: Seamless data integration via TCP/IP allows for remote monitoring and real-time weight reporting accessible from any global location via the internet.

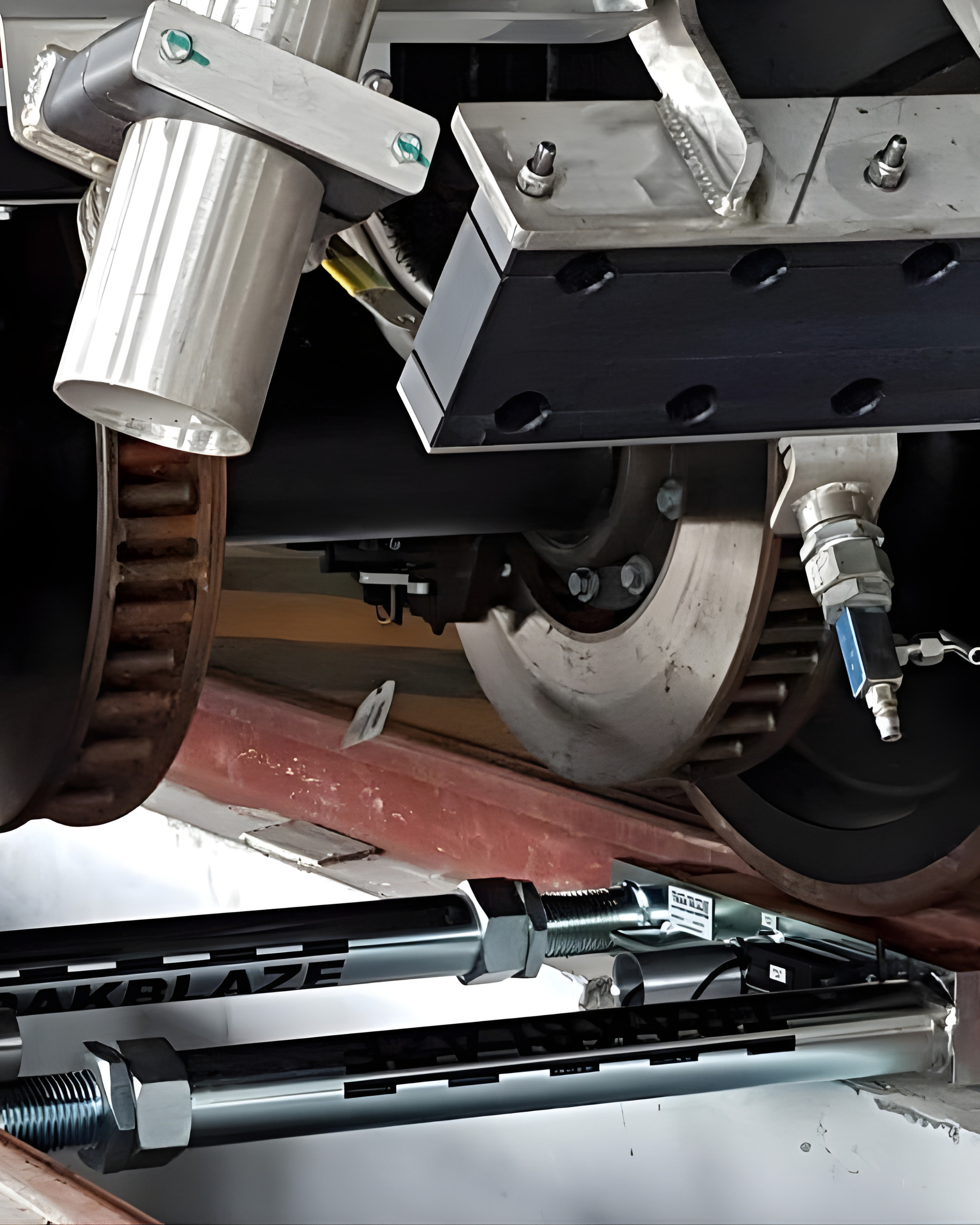

Mobile Train Weigher & Balancing System – MTW-MS

Portable Precision: "Take the Scale to the Train"

The MTW-MS is a versatile, mobile weighing and balancing solution designed for rapid deployment. It is an essential tool for field spot-checks, rail manufacturing, and maintenance depots requiring precise wheel, axle, and bogie balancing to prevent derailments.

Portability & Deployment: The system is lightweight and compact enough to be transported in the boot of a standard vehicle. A two-man team can complete the installation in approximately 15–30 minutes without any track downtime or costly civil works.

Balancing & Multi-System Capability:

Advanced Balancing: The MTW-MS measures individual wheel, axle, and bogie weights, providing the data necessary to adjust load distribution and simulate operational stresses.

Scalability: Supports the connectivity of up to 8 or 12 base units to weigh multiple bogies or entire railcars simultaneously.

Technical Specifications:

Capacity: Standard capacity of 17.5t per wheel (35t per axle), with heavy-duty options available.

Static & Dynamic Modes: Engineered for both stationary weighing (accuracy ±0.5%) and in-motion "spot check" weighing.

Environmental Protection: Built with high-quality tool and mild steel, featuring IP-67 or IP-68 protection ratings to withstand harsh outdoor and workshop conditions.

Wireless Connectivity: Modern configurations utilize wireless receivers and rugged tablets, eliminating the need for cables and allowing for greater operational flexibility in complex workshop environments.

Railways –

SaaS & Digital Solutions

Intelligent Software Platforms for Smarter Rail Operations

Klovertel’s Railways SaaS offerings extend beyond hardware into intelligent, cloud-driven software systems that enable real-time visibility, predictive insights, and enhanced operational control across railway fleets. Our digital solutions are designed to integrate seamlessly with onboard systems and central command infrastructure, supporting modern, data-driven rail networks.

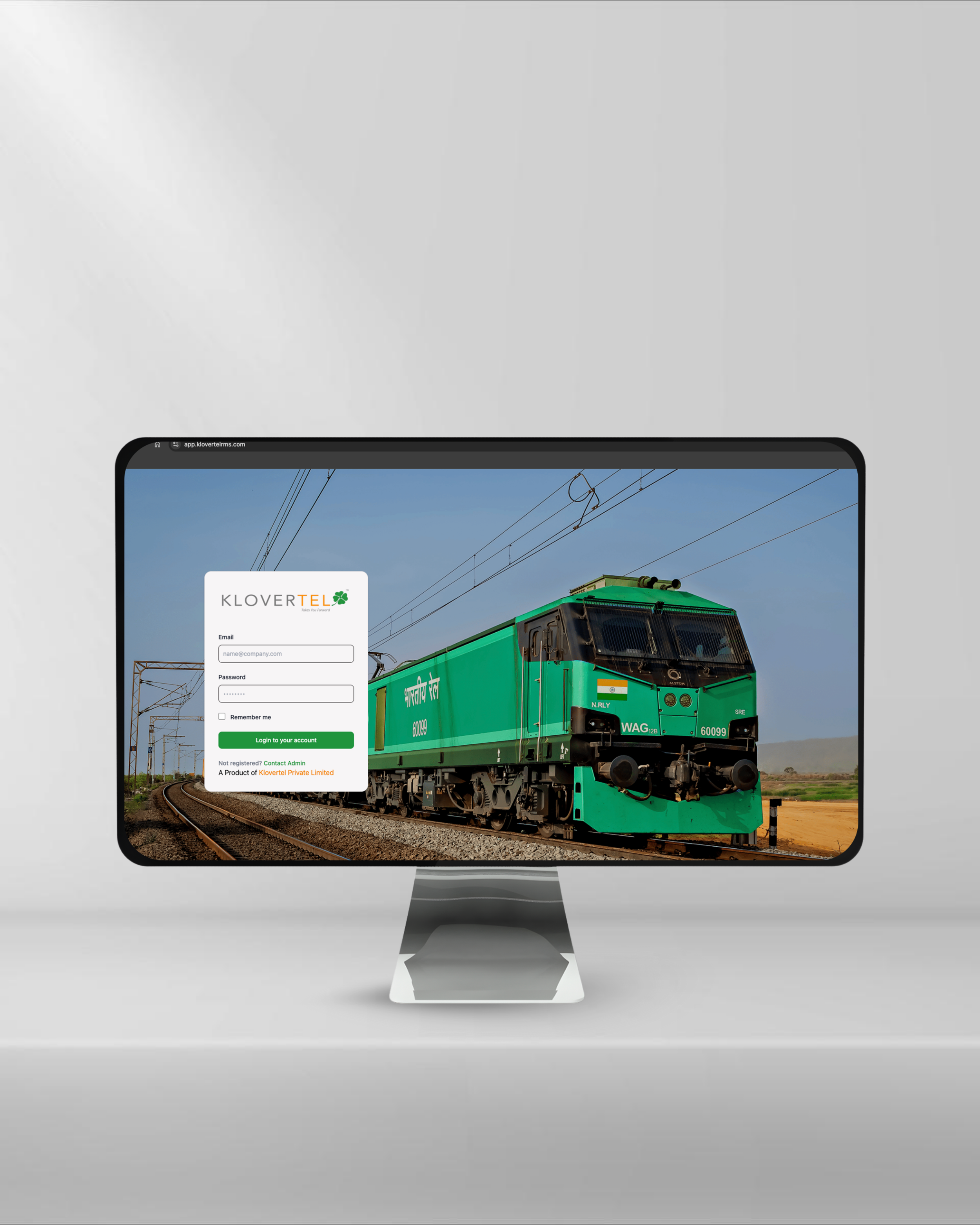

Intelligent Fleet Management (RMS Cloud)

Our RMS Cloud platform enables centralized, real-time monitoring of locomotive health and performance.

Cloud-native architecture for live visualization of critical locomotive parameters

Secure, role-based web portals for fleet-wide monitoring and control

Unified dashboards for operational teams, maintenance planners, and decision-makers

Scalable deployment across fleets and railway zones

Predictive Maintenance Analytics

We leverage AI/ML-driven analytics to transform operational data into actionable insights.

Advanced dashboards analysing historical and real-time data streams

Early fault detection and failure prediction before breakdowns occur

Optimised maintenance schedules that reduce unplanned downtim

Improved asset life cycle management and operational efficiency

HMI & Onboard Software Systems

Klovertel designs and deploys intuitive onboard software solutions for modern train control environments.

Custom Human Machine Interface (HMI) software for driver-friendly and safe train operations

Proven deployments, including high-speed and semi-high-speed trainsets such as Vande Bharat

Seamless integration with TCMS, DPWCS, and other onboard control systems

High-reliability software designed for mission-critical railway applications

By combining cloud platforms, analytics, and onboard software, Klovertel delivers an end-to-end digital ecosystem for railways — enabling smarter operations, predictive decision-making, and future-ready infrastructure.